|

Designation |

CT-1880 |

CT-1885 |

CT-1890 |

CT-1895 |

CE-1885 |

|

Below test results were from our TPU film of thickness 1.0m/m |

|

Hardness ±2 |

80A |

85A |

90A |

95A |

85A |

300% Modulus

|

50 |

70 |

80 |

140 |

85 |

Tensile Strength

(Kg/cm2) |

230 |

320 |

340 |

400 |

330 |

Elongation(%)

|

800 |

600 |

550 |

500 |

600 |

Tear strength

|

75 |

90 |

100 |

125 |

90 |

Specific Gravity

(±0.02) |

1.2 |

1.2 |

1.2 |

1.22 |

1.12 |

|

Melt point ±5℃ |

70 |

100 |

110 |

130 |

100 |

UV Resistance 24hr

(grade) |

4 |

4 |

4 |

4 |

4 |

|

Hydiolysis Resistance |

Good |

Good |

Good |

Good |

Excellent |

|

H/F welding level |

Excellent

|

Excellent

|

Excellent

|

Good |

Excellent

|

|

|

※ properties listed for reference only, actual data to test the actual film as the standard. (Thickness specifications: 0.1 ~ 2.0mm)

※ Where necessary requirements other things, the company also with the development and mass production.

※ another film after processing series: electroless plating, change color film, laminating or processing of all kinds of lines, etc ...... |

|

|

TPU products according to different production methods have their different methods and types of post-processing |

|

1、Blown class

- |

Typically bonded patch manner as

clothing, medical appliances or shoe

with a waterproof and |

| |

breathable. |

|

|

2、Extrusion class

- |

TPU film extrusion in terms of the use that is more and post-processing methods, such as |

|

◎ |

High Frequency - Pneumatic molding, eager to make the substrate Logo or decorations. |

|

◎

|

Printing、change color - Screen printing, heat transfer, water transfer, knife, roller, co-paste PU Skin. |

|

◎ |

Stickers reflective film |

|

◎ |

Stick together - Stick knitting / weaving, stick plating / Ray Zhimo. |

|

◎

|

Vacuum - As air bags, oil, computer keyboards, dust cover. |

|

◎ |

Embossed |

|

◎ |

Glue- LCD protective film, waterproof, electronic tape. |

|

◎ |

With injection- Injection, injection outsole use. |

|

|

3、Injection

class

- |

Generally speaking directly after

the injection can be used mostly

finished, and then after |

| |

processing For who posted are based on

re-painting and electroplating

based. |

|

|

|

|

|

| |

|

1、 |

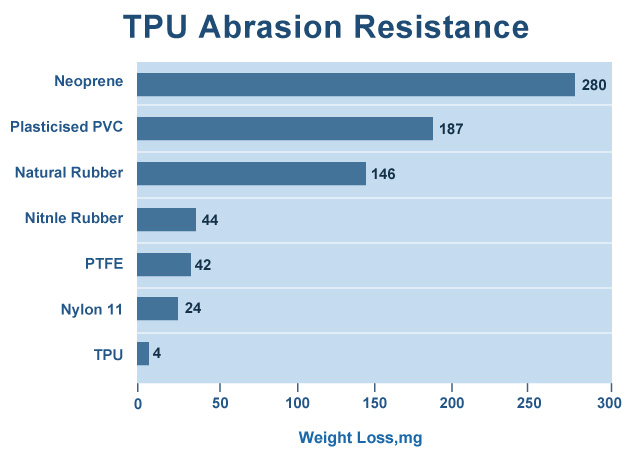

Abrasion & abrasion Hao is very good. |

|

2、 |

Tear good tensile strength. |

|

3、 |

Oil, Gasoline resistance is good. |

|

4、 |

Low-temperature characteristics of a good flexible, weather resistance, ozone resistance. |

|

5、 |

Ichiban Health Act in line with FDA regulations. |

|

6、 |

Wide range of hardness, elasticity softness cept, large shock-absorbing silencer. |

|

7、 |

Transparency, versatile, good workability. |

|

8、 |

It can meet the environmental requirements & recycling processing cost savings. |

|

9、 |

Easily mixed with other resins. |

|

10、 |

The solvent can dissolve after processing. |

|

|

|

| Back |

|